Not all repairs are created equal. Recently, we encountered a perfect example of why choosing the right repair shop matters when it comes to your expensive devices. An iPhone 12 Pro Max arrived at our workshop with an unusual problem – the replacement screen wouldn’t work, despite another repair shop having “completed” the job.

The Problem: More Than Just a Faulty Screen

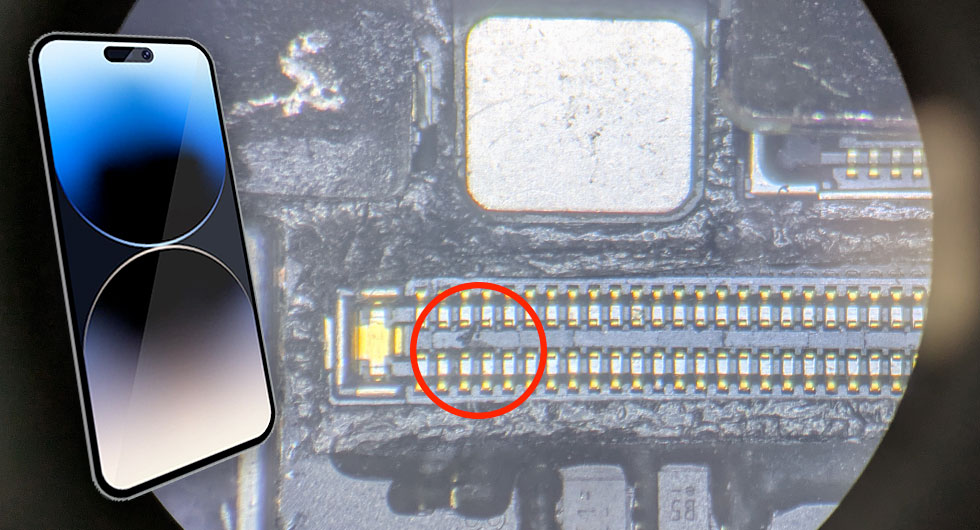

When we examined the device under our microscope, the issue became immediately clear. Part of a connector had been broken off and left embedded in the logic board socket. This wasn’t a faulty screen issue at all – it was the result of careless repair work that had damaged the delicate internal components.

The previous repair attempt had snapped off part of the display connector, leaving debris that prevented the new screen from establishing a proper connection. Without the right tools and expertise, this type of damage can render an otherwise functional iPhone completely unusable.

Why Connector Damage Happens

Display connectors on modern iPhones are incredibly delicate. They require precise handling and the correct tools to disconnect and reconnect safely. Common causes of connector damage include:

Incorrect Tools

Using the wrong tools—or worse, improvised alternatives—puts excessive force on fragile components. Proper spudgers and precision tweezers are essential for working with these tiny connectors.

Rushing the Job

Taking shortcuts or working too quickly increases the risk of damaging connectors. Each connection point needs careful attention during both removal and installation.

Lack of Experience

Without proper training and experience with microelectronics, it’s easy to apply force in the wrong direction or at the wrong angle, leading to broken pins or torn sockets.

The Repair Process

Removing embedded connector fragments requires specialist equipment and a steady hand. Using a microscope, we carefully extracted the broken piece without causing further damage to the surrounding components. Once the socket was clean, we tested the connection with a known-working screen to verify functionality before fitting the customer’s replacement display.

Lessons for Device Owners

This repair highlights several important points for anyone considering screen replacement:

Choose experience over price. The cheapest option isn’t always the best value, especially when a botched repair can make your device worse—or even irreparable.

Ask about equipment. Professional repair shops invest in proper tools, including microscopes and precision instruments for delicate work.

Check credentials. Look for technicians with proven experience in microsoldering and board-level repairs, not just basic screen swaps.

Understand the risks. Even straightforward repairs can go wrong in inexperienced hands, potentially turning a simple screen replacement into a complex data recovery situation.

The Outcome

After removing the broken connector fragment and thoroughly cleaning the socket, we successfully fitted the replacement screen. The iPhone 12 Pro Max powered on perfectly, with full touch functionality and display quality restored.

What should have been a routine screen replacement became a rescue mission due to poor initial workmanship. The customer left with a working phone, but the experience could have been avoided entirely with the right choice of repair shop from the start.

Prevention Is Better Than Cure

Modern smartphones contain some of the most sophisticated miniaturised technology available to consumers. Treating them with the care and expertise they deserve ensures your iPhone repair goes smoothly the first time, saving you time, money, and considerable stress.

When your device needs repair, taking the time to choose a qualified, well-equipped technician isn’t just about getting your phone back faster—it’s about protecting your investment and ensuring you don’t end up with more problems than you started with.